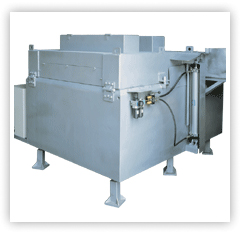

Radiant holding furnace

The main body of the furnace is made of one-piece casted interior. The insulating material is low thermal conductivity, and None-Wetting refractory materials, which can lock the heat within the molten Aluminum. Furthermore, insulating boards are precisely calculated to make sure heat does not escape. This allows us to reduce the heat-loss. Therefore, it saves energy, maintains stable quality of molten aluminum and improves the temperature of working environment. Since it is not made up of crucible the furnace can operate more economically, conveniently, and safely.

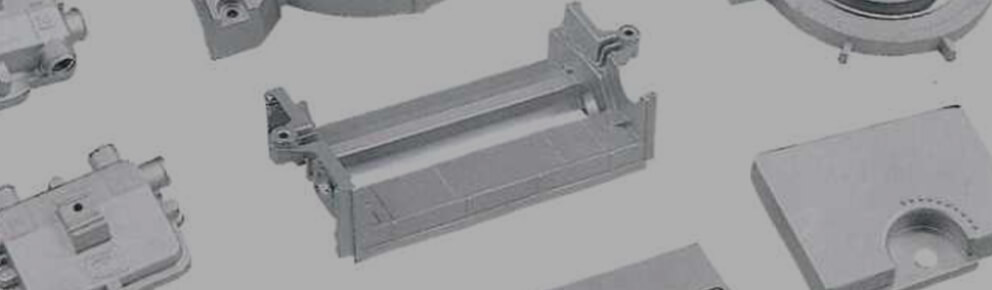

GP-H800 Exterior

Our furnace offers 2 types of opening, 1 hanging type and air pressured cylinder opener. In order not to interfere with the overhead crane the air pressured type is more preferred.

Energy saving holding furnace: The furnace is designed for reduced labor and less energy consumption. The only exhaustion of the heat energy is from the dipping pool which we emphasis to size down as much as possible. We set the SCR proportion control in the furnace according to customers¡ requirement. With this specially designed approach, the inclined interior increases the heat energy in the furnace to make it even more efficient but less holding capacity than the GP-H800 version.

Furnace specialty:

- Fuel efficient

The holding consumption of electricity for 500kg is 3.0KW/H, when heaters are in full throttle the electricity consumption is 6.0 KW/H. - Pollution free

No noises, no air pollution and improves the temperature of working environment. - Long service life

Since the interior is made up of special insulating material the molten aluminum is not easy to stock on the interior, and of course there is no worry of leakage, which causes danger. - Stable temperature

Both molten aluminum, heater temperature are controlled by SCR therefore, the quality of the aluminum is assured. - Easy maintenance

When cleaning the furnace, changing heater, the upper part of the furnace can simply be lift up for service.

| Model No. | Capacity (kg) | Dipping pool size1XW (mm) | Diagonal (mm) | Depth (mm) | Outline size LX W (mm) | Electricity (KW) | Suitable machine | Electricity consumption |

|---|---|---|---|---|---|---|---|---|

| GP-H200 | 600 | 350 x 350 | 475 | 400 | 1540 x 1380 | 15.0; | Below 200 TON | 7.5kw |

| GP-H550 | 1000 | 350 x 350 | 475 | 450 | 1880 x 1495 | 15.0 | Below 350 TON | 7.5kw |

| GP-H800 | 1200 | 450 x 450 | 660 | 450 | 2035 x 1495 | 21.0 | Below 800 TON | 7.5kw |

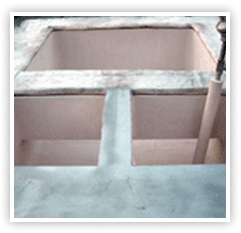

Dipping Pool

The dimension of the dipping pool must be confirmed prior to manufacture? Correct size will minimized the lost of energy and prolongs the life cycle of the furnace.

* Furnace is able to adjust up and down for 10 cm; dipping pool height is 115 cm (GP-H500, GP-H800), 110cm (GP-H200)

Other Specs

Main control and over heating protection control: Main control is the SCR; o over heating protection control will be automatic controlled by the heating components. We also manufacture pouring bowl for aluminum deliver during production. Pouring bowl interior is also provided by FOSECO.